저희 회사의 최우선 목표는 고객 여러분께 성실하고 책임감 있는 비즈니스 관계를 제공하고, OEM/ODM 방식으로 생산되는 중국산 ANSI B16.5 Grade2 150# 프레스 등급 스테인리스 스틸 블라인드 플랜지 DN200 DIN 2573 Pn16 플레이트 플랜지(가스 산업용)에 대해 맞춤형 서비스를 제공하는 것입니다. 저희 회사와 공장을 방문해 주시면 감사하겠습니다. 추가적인 도움이 필요하시면 언제든지 연락 주시기 바랍니다.

저희의 주된 목표는 고객들에게 진지하고 책임감 있는 비즈니스 관계를 제공하고, 모든 고객에게 맞춤형 서비스를 제공하는 것입니다.중국 자동차 부품, 판막저희 회사의 사명은 고품질의 아름다운 제품을 합리적인 가격에 제공하고 고객으로부터 100% 좋은 평판을 얻는 것입니다. 저희는 전문성이 탁월함을 이룬다고 믿습니다! 저희와 협력하여 함께 성장해 나가기를 기대합니다.

사양

| 제품명 | 플레이트 플랜지 |

| 크기 | 1/2"-250" |

| 압력 | 150#-2500#,PN0.6-PN400,5K-40K,API 2000-15000 |

| 기준 | ANSI B16.5,EN1092-1, SABA1123, JIS B2220, DIN, GOST,UNI,AS2129, API 6A 등 |

| 벽 두께 | SCH5S, SCH10S, SCH10, SCH40S, STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS 등 |

| 재료 | 스테인리스 스틸:A182F304/304L, A182F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571, 1.4541, 254Mo 등 |

| 탄소강:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 등 | |

| 듀플렉스 스테인리스강: UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462, 1.4410, 1.4501 등 | |

| 파이프라인용 강철:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 등 | |

| 니켈 합금:인코넬600, 인코넬625, 인코넬690, 인콜로이800, 인콜로이825, 인콜로이800H, C22, C-276, 모넬400, 알로이20 등 | |

| 크롬-몰리브덴 합금:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3, 15Crmo 등 | |

| 애플리케이션 | 석유화학 산업, 항공우주 산업, 제약 산업, 배기가스, 발전소, 조선업, 수처리 등 |

| 장점 | 즉시 배송 가능, 빠른 배송, 모든 사이즈 제공, 맞춤 제작 가능, 고품질 |

치수 표준

제품 상세 정보 보기

1. 얼굴

레이즈드 페이스(RF), 풀 페이스(FF), 링 조인트(RTJ), 그루브, 텅 또는 맞춤형으로 제작 가능합니다.

2. 얼굴 밀봉

매끄러운 얼굴, 점막, 톱니 모양 마감

3. CNC 정밀 가공.

표면 조도: 플랜지 표면 조도는 산술 평균 조도 높이(AARH)로 측정됩니다. 조도는 사용되는 표준에 따라 결정됩니다. 예를 들어, ANSI B16.5는 125AARH~500AARH(3.2Ra~12.5Ra) 범위의 표면 조도를 규정합니다. 요청 시 1.6Ra(최대), 1.6/3.2Ra, 3.2/6.3Ra 또는 6.3/12.5Ra와 같은 다른 조도도 제공 가능합니다. 3.2/6.3Ra 범위가 가장 일반적입니다.

표시 및 포장

• 각 층에는 표면 보호를 위해 플라스틱 필름이 사용됩니다.

• 모든 스테인리스 스틸 제품은 합판 케이스에 포장됩니다. 대형 탄소강 플랜지는 합판 팔레트에 포장됩니다. 또는 맞춤형 포장도 가능합니다.

• 배송 표시는 요청 시 제작 가능합니다.

• 제품에는 조각 또는 인쇄 방식으로 표시를 할 수 있습니다. OEM 생산도 가능합니다.

점검

• UT 테스트

• 체력 테스트

• MT 테스트

• 치수 테스트

납품 전, 당사 품질관리팀에서 비파괴검사(NDT) 및 치수 검사를 진행합니다. 제3자 검사(TPI)도 허용합니다.

협력 사례

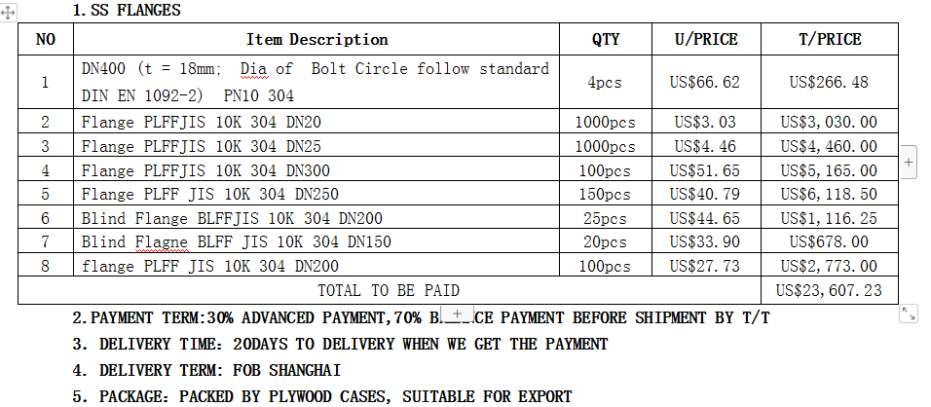

이 주문은 베트남 재고 보유업체용입니다.

생산 공정

| 1. 정품 원료를 선택하세요 | 2. 원자재 절단 | 3. 예열 |

| 4. 단조 | 5. 열처리 | 6. 황삭 가공 |

| 7. 드릴링 | 8. 정밀 가공 | 9. 표시 |

| 10. 점검 | 11. 포장 | 12. 배송 |

저희 회사의 최우선 목표는 고객 여러분께 성실하고 책임감 있는 비즈니스 관계를 제공하고, OEM/ODM 방식으로 생산되는 중국산 ANSI B16.5 Grade2 150# 프레스 등급 스테인리스 스틸 블라인드 플랜지 DN200 DIN 2573 Pn16 플레이트 플랜지(가스 산업용)에 대해 맞춤형 서비스를 제공하는 것입니다. 저희 회사와 공장을 방문해 주시면 감사하겠습니다. 추가적인 도움이 필요하시면 언제든지 연락 주시기 바랍니다.

OEM/ODM 중국 자동차 부품, 밸브 전문 기업인 저희 회사는 합리적인 가격으로 고품질의 아름다운 제품을 제공하고 고객 만족도 100%를 달성하는 것을 사명으로 삼고 있습니다. 전문성이 곧 탁월함을 이룬다고 믿습니다! 저희와 협력하여 함께 성장해 나가기를 기대합니다.

제품 상세 정보 보기

1. 얼굴

레이즈드 페이스(RF), 풀 페이스(FF), 링 조인트(RTJ), 그루브, 텅 또는 맞춤형으로 제작 가능합니다.

2. 얼굴 밀봉

매끄러운 얼굴, 점막, 톱니 모양 마감

3. CNC 정밀 가공.

표면 조도: 플랜지 표면 조도는 산술 평균 조도 높이(AARH)로 측정됩니다. 조도는 사용되는 표준에 따라 결정됩니다. 예를 들어, ANSI B16.5는 125AARH~500AARH(3.2Ra~12.5Ra) 범위의 표면 조도를 규정합니다. 요청 시 1.6Ra(최대), 1.6/3.2Ra, 3.2/6.3Ra 또는 6.3/12.5Ra와 같은 다른 조도도 제공 가능합니다. 3.2/6.3Ra 범위가 가장 일반적입니다.

표시 및 포장

• 각 층에는 표면 보호를 위해 플라스틱 필름이 사용됩니다.

• 모든 스테인리스 스틸 제품은 합판 케이스에 포장됩니다. 대형 탄소강 플랜지는 합판 팔레트에 포장됩니다. 또는 맞춤형 포장도 가능합니다.

• 배송 표시는 요청 시 제작 가능합니다.

• 제품에는 조각 또는 인쇄 방식으로 표시를 할 수 있습니다. OEM 생산도 가능합니다.

점검

• UT 테스트

• 체력 테스트

• MT 테스트

• 치수 테스트

납품 전, 당사 품질관리팀에서 비파괴검사(NDT) 및 치수 검사를 진행합니다. 제3자 검사(TPI)도 허용합니다.

협력 사례

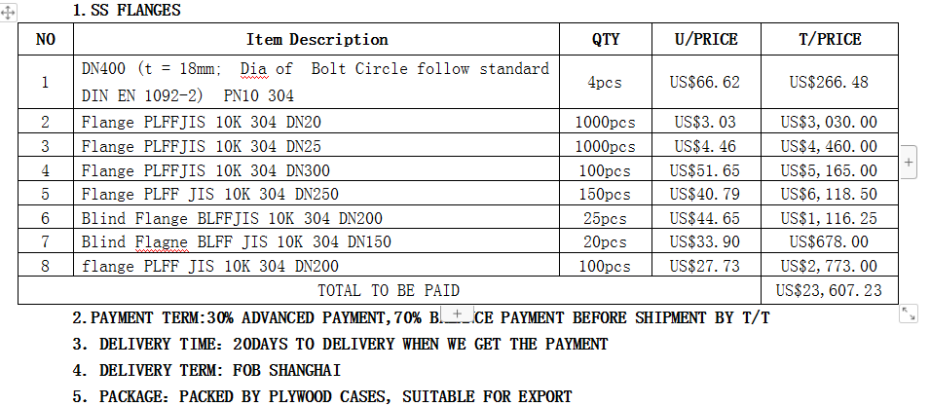

이 주문은 베트남 판매점용입니다.

생산 공정

| 1. 정품 원료를 선택하세요 | 2. 원자재 절단 | 3. 예열 |

| 4. 단조 | 5. 열처리 | 6. 황삭 가공 |

| 7. 드릴링 | 8. 정밀 가공 | 9. 표시 |

| 10. 점검 | 11. 포장 | 12. 배송 |

배관 부속품은 배관 시스템에서 연결, 방향 전환, 유량 변경, 크기 조절, 밀봉 또는 유체 흐름 제어에 사용되는 중요한 구성 요소입니다. 건설, 산업, 에너지 및 도시 서비스 등 다양한 분야에서 널리 사용됩니다.

주요 기능:이 장비는 파이프 연결, 흐름 방향 변경, 흐름 분할 및 합류, 파이프 직경 조정, 파이프 밀봉, 제어 및 조절과 같은 기능을 수행할 수 있습니다.

적용 범위:

- 건물 급수 및 배수 시스템:PVC 엘보와 PPR 삼각관은 수도관망에 사용됩니다.

- 산업용 파이프라인:스테인리스강 플랜지와 합금강 엘보는 화학 물질을 이송하는 데 사용됩니다.

- 에너지 운송:고압 강관 부속품은 석유 및 가스 파이프라인에 사용됩니다.

- HVAC(난방, 환기 및 공조):구리 파이프 부속품은 냉매 배관을 연결하는 데 사용되며, 유연한 연결 부품은 진동 감소에 사용됩니다.

- 농업용 관개:퀵 커넥터는 스프링클러 관개 시스템의 조립 및 분해를 용이하게 합니다.